Safety: Technical Intervention in Classified Areas

As part of interventions in petrol stations, there is a number of working areas defined and characterized as dangerous. A dangerous area is any area with conditions prone to the formation of an explosive atmosphere in concentrations that require the adoption of special precautions in order to ensure the safety and health of the employees who work there.

But what are explosive atmospheres?

An explosive atmosphere is defined as a mixture of flammable substances with air, under atmospheric conditions, in the form of gas, vapours, mist or dust in which, after ignition has occurred, combustion spreads to the entire unburned mixture.

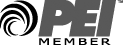

Hazardous areas are classified into zones based on an assessment of the frequency of the occurrence and duration of an explosive gas atmosphere, as follows:

Zone 0 - An area in which an explosive atmosphere comprising a mixture of flammable substances with air, in the form of gas, vapours, mist or dust is present continuously, for long periods, or frequently.

Zone 1 - An area in which an explosive atmosphere comprising a mixture of flammable substances with air, in the form of gas, vapours, mist or dust is likely to occur under normal operating conditions.

Zone 2 - An area in which an explosive atmosphere comprising a mixture of flammable substances with air, in the form of gas, vapours, mist or dust is not likely to occur under normal operating conditions. If it occurs, it will only exist for a short time.

So, which precautions should be mandatorily taken before any intervention in areas classified as dangerous?

Before starting any work or task, you should always carry out a Task Safety Analysis (TSA), asking yourself what could go wrong. According to the work that needs to be carried out, you should check whether you have the knowledge and equipment to perform the task safely, assess risks and define preventive measures. You must never start a job if you have doubts regarding safety issues!

Once all the safety conditions are met, you should focus on the use of personal protective equipment (PPE). PPE is any type of equipment, part or accessory intended to be used by employees who are exposed to safety and health risks to protect themselves.

Then, the working area needs to be properly cordoned-off. In order to do that, you need to limit the access to the area of intervention by third parties and ensure that there is enough information to keep them away and aware of the context of the intervention in a dangerous area. This warning sign indicates the existence of explosive substances, explosive mixtures or explosive atmospheres. In Europe, its use is regulated as mandatory:

In order to be prepared in case of emergency, you should also place fire extinguishers in accessible locations across the working area. Finally, you should monitor the working atmosphere using an explosimeter. Once the required safety conditions are met, you can start working.

Over 25 years of experience, safety has been one of the main concerns, not only of Petroassist as a company, but of the entire Petrotec Group as a whole.

Petroassist provides technical assistance as part of the maintenance and repair of multibrand equipment for the oil industry 365 days a year, 24 hours a day, in all the markets where it operates directly (Portugal, Spain, the United Kingdom, Angola, Mozambique and South Africa) thanks to a large team of technical assistants, all of whom are trained and qualified to work safely in all types of environments.

Find out more about the various areas where Petroassist operates, here.